Now Reading: Daily Maintenance Tips for Your DTF Printer

-

01

Daily Maintenance Tips for Your DTF Printer

Daily Maintenance Tips for Your DTF Printer

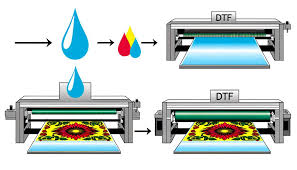

The ideal working conditions of a DTF printer are, however, highly dependent on its maintenance, and incorrectly performed preventative maintenance can lead to troubles such as clogs within the nozzles, altered quality of the end product, and expensive repairs down the road. With this in mind, the article focuses on suggesting maintenance practices targeted to be performed on a day to day basis to enhance the performance of a DTF Printer.

Cleaning the Printer

The recurring action in the printer maintenance practice is regular printer cleaning and because this action has to happen at least once a day, it is classified as a daily chore. Cleaning for the first time should include gently wiping the dust and debris off the outer case of the printer with soft clothes. The print head and platen areas must be closely monitored since they are the most efficient suspects for ink accumulation.

Once every week focus on doing a more intense cleaning of the print heads as an example. We understand that most DTF printers have cleaning cycles that can be done using printer settings – as this is the case with almost any DTF printer. This infrastructure basically unclogs and facilitates even ink flow and if clogged, always look out for draws and streaks in prints and manually clean printer heads with the right solution designed for said printer.

Checking and Replacing Parts

Check some of the most often used parts of your printer, ink cartridges, print heads or capping station, once in a while. Also, ensure definitely that when switching to certain cartridges the ink will always be enough and the process will not be broken, otherwise replace the cartridges that are low. Last but not the least, check for damaged or worn out print heads – and if they are too far gone, swap them out.

Calibration

Regularly calibrating your printer is very important in regard to the quality of prints. It entails modifying printer configurations to achieve correct color reproduction and correct placement of the design onto the apparel. Fortunately, most printers are equipped with calibration tools that help one easily perform the calibration.

Troubleshooting Common Issues

You can save yourself time and money if you take the initiative to correct common problems. For instance, if you start noticing your prints are not coming out crisp or are always faint, then first look at the ink levels and perform a print head cleaning. In case of any issues regarding the transfer film sticking problems, make sure that the heat press is set at the specified temperature and pressure.

Conclusion

Maintenance performed on a daily basis cannot be overemphasized at all since it enhances the life expectancy and performance levels of a DTF printer. In accordance with these recommendations, however, the printer can perform its functions properly and provide quality prints according to expectations. Regular maintenance not only improves the performance of your devices but also the quality of the printing process as a whole.